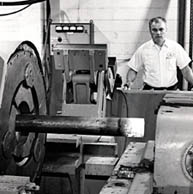

PTS distinguishes itself by the range of shaft and roll sizes offered plus the secondary machining, grinding, slotting and coating.

We offer aid in design and CAD services as well as emergency service, on-time delivery and 48 hour single piece production.

Our exclusive, patented design includes "rigitizing" with a solid foam core, which dampens resonant frequencies and provides a safety factor for the critical-speed design of your equipment.

All shafts are single-piece construction, with swaged journals integral to the tubular body, and are dynamically balanced. The drive end is extra heavy to assure maximum torsional strength.

PTS has developed extensive data relative to the forging or swaging of journals integral to the tube, used as the shaft or roll body.

Micrographic analysts and destructive testing have validated strength increased in the forged end section resulting in dramatic grain refinement of the steel structure affording greater toughness characteristics typical of the forging process, X-ray defraction analysis records no residual stresses for the PTS process which aids holding close tolerances during the further processing of PTS shafting.

Complete metallurgical data regarding the integrity of the process and product is available on request by an authorized customer representative that guarantees to review the data in the best interest of PTS.